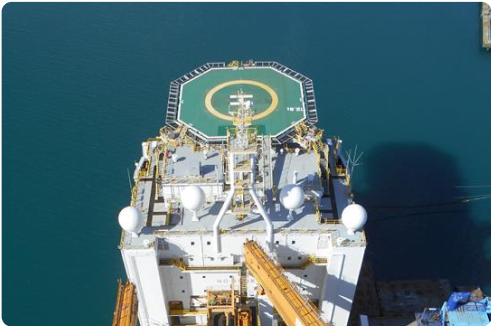

RigQuip was engaged by the owners of a modern, 7th gen ultra deepwater drillship to carry out inspection and service of pipe handling equipment, a complete mud system and a range of other ancillary equipment as part of a major rig reactivation scope. Our team deployed to provide a smart, cost-effective solution to recertify the onboard systems during the vessel’s extended stacking period.

Challenge

A large volume of modern, high specification NOV equipment was required to be brought back online quickly. Limited maintenance had been carried out during the vessel’s extended stacking period. High quality inspections and reporting as well as meaningful, auditable maintenance was essential.

Solution

The scope was delivered by our experienced on site team utilising our API Q2 certified RigPartner drilling equipment maintenance system. RigPartner provides high quality procedures and technical content to our teams in the field and facilitates rapid reporting, documentation and remote technical support.

Pipe Handling

Top Drive Pipe Handlers

Knuckleboom Crane

Fingerboards

Pipe Handling Catwalk

Riser Handling Catwalk

Wireline Riser Tensioners

Hydraulic Catheads

Power Slips

Mud System

Mud Pumps

Shakers

Centrifuges

Mud Mixing System & Tanks

Pumps, Agitators & Desilters

Mud Gas Separators

Vacuum Degassers

Mud System & Other Valves

Bulk Transfer System

Cement/Barite System

Ancillary Equipment

BOP Gantry Crane

BOP Trolley & Test Stump

Xmas Bridge Crane & Trolley

Hose Reel Stations & Winches

Hydraulic Pressure Units

Pipe Handling

Top Drive Pipe Handlers

Knuckleboom Crane

Fingerboards

Pipe Handling Catwalk

Riser Handling Catwalk

Wireline Riser Tensioners

Hydraulic Catheads

Power Slips

Mud System

Mud Pumps

Shakers

Centrifuges

Mud Mixing System & Tanks

Pumps, Agitators & Desilters

Mud Gas Separators

Vacuum Degassers

Mud System & Other Valves

Bulk Transfer System

Cement/Barite System

Ancillary Equipment

BOP Gantry Crane

BOP Trolley & Test Stump

Xmas Bridge Crane & Trolley

Hose Reel Stations & Winches

Hydraulic Pressure Units