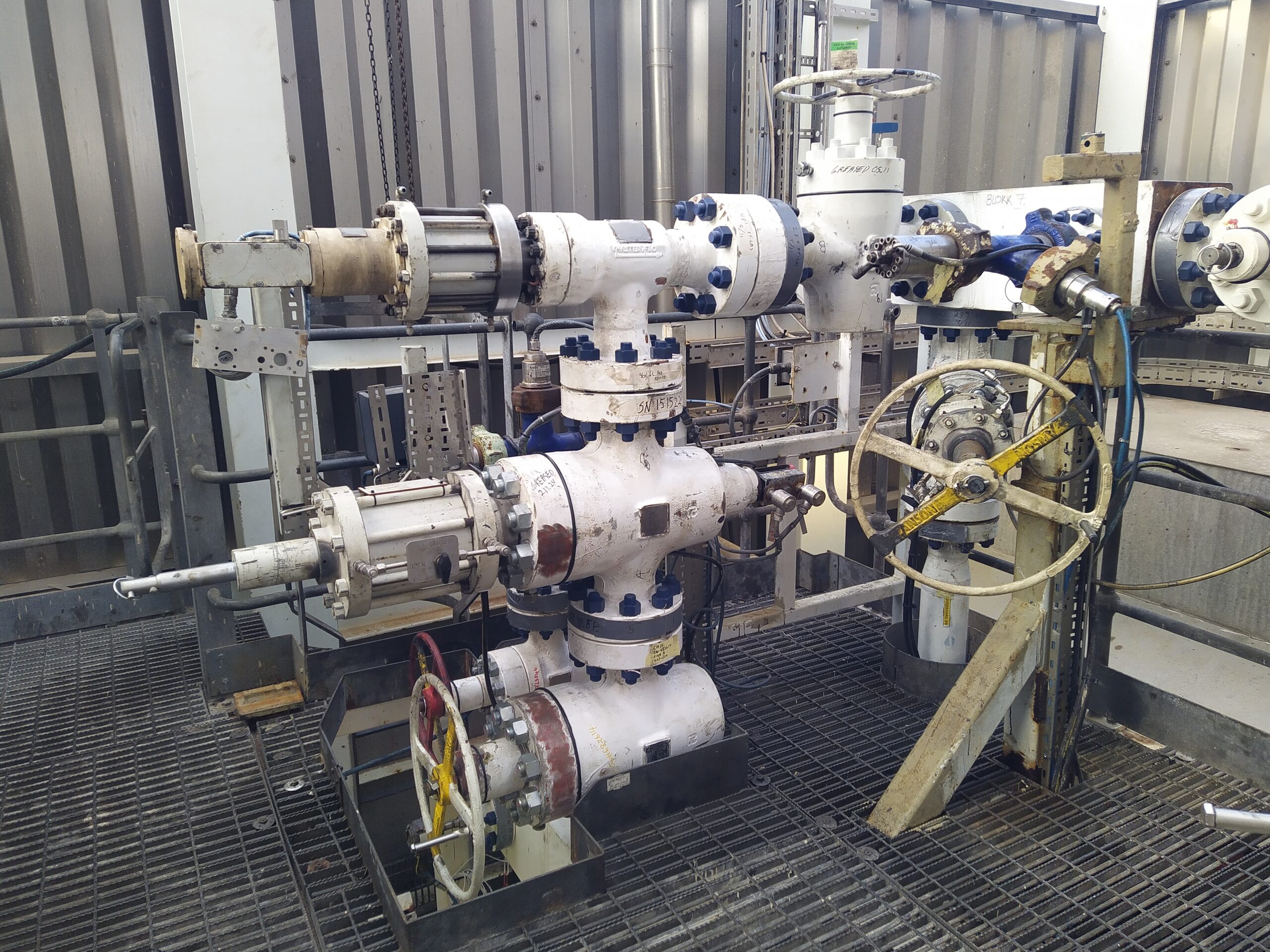

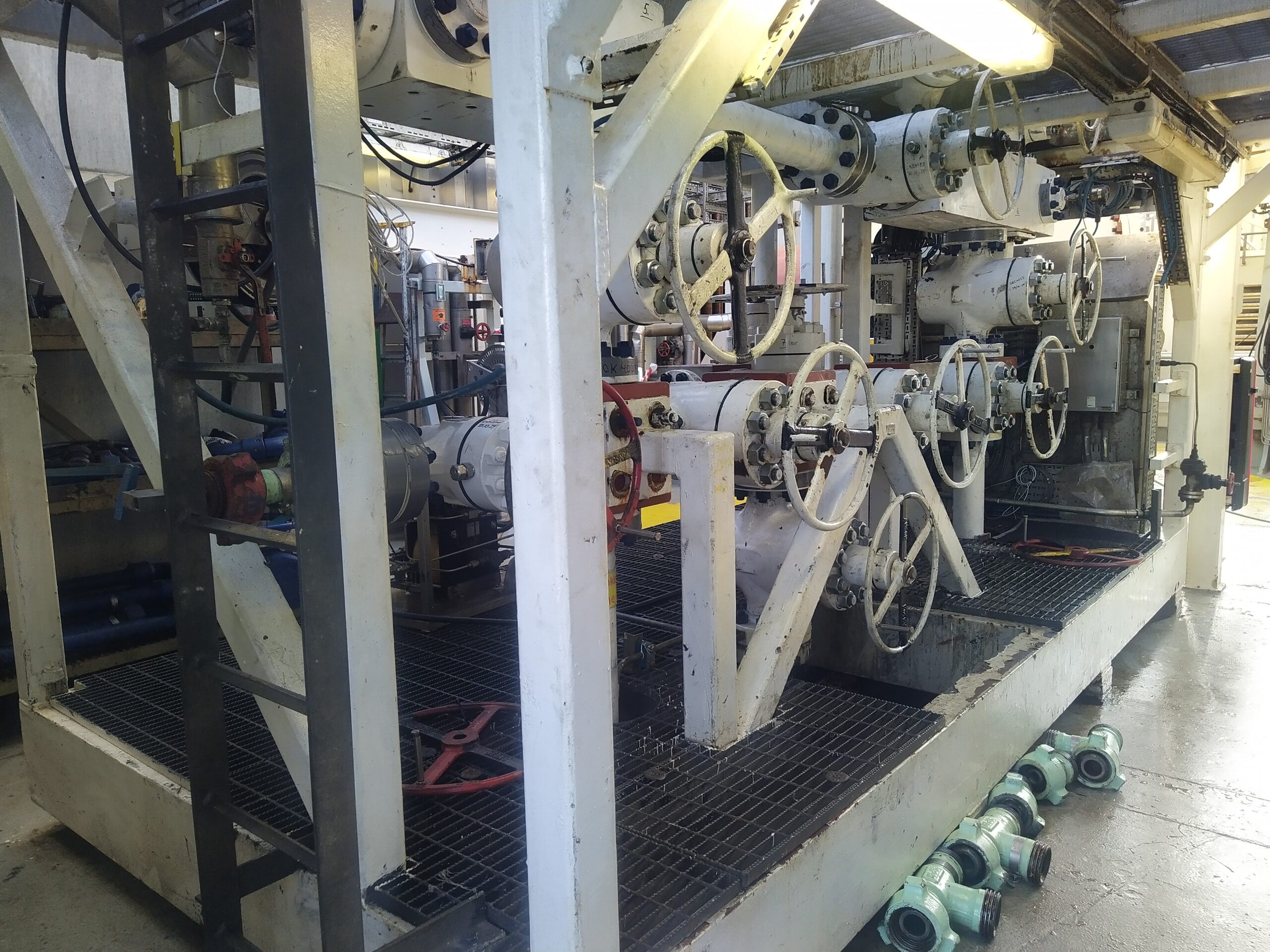

RigQuip recently carried out a field based, five yearly inspection, overhaul and recertification of a high specification NOV Shaffer choke & kill manifold. The team mobilised to a 6th generation, harsh environment semi-sub in West Africa which we visited for the units last recertification in 2019. All work was completed in accordance with API 16C, API 6AR and API 6A.

Challenge

The rig had been cold stacked in Las Palmas for some time and the equipment needed to be overhauled and recertified in a short timeframe to meet the deadline for its next drilling contract. High quality auditable work was essential as the vessel was going to work for a premium operator in the Norwegian North Sea sector.

Solution

RigQuip deployed an experienced team of service engineers and completed the work in the required time aided by RigPartner, our API Q2 certified drilling equipment maintenance system. This provides high quality procedures and technical content to our field teams, allows subject matter experts to provide remote support, and assists with automated reporting and documentation.

Pipe Handling

Gate valves

Choke valves

Flanges

Spools

Elbows

Tees

Blocks

Crossovers

Gauges

Controls

Hoses

Electrical components

Repair kits

Replacement valves

Pipe Handling

Gate valves

Choke valves

Flanges

Spools

Elbows

Tees

Blocks

Crossovers

Gauges

Controls

Hoses

Electrical components

Repair kits

Replacement valves